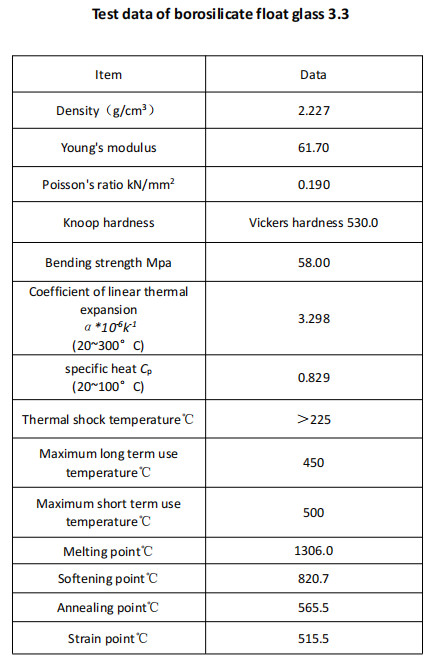

Bakeng sa Boleng bo Phahameng, Borosilicate Float Glass 3.3: Perfect Semiconductor Chip

Kenyelletso ea Sehlahisoa

Litšobotsi tse ka sehloohong tsa khalase e phahameng ea borosilicate 3.3 ke: ha ho peeling, e seng chefo, e sa latsoeheng; Ponahalo e ntle, ponahalo e hloekileng le e ntle, mokoallo o motle, o phefumolohang, lisebelisoa tsa khalase tse phahameng tsa borosilicate, o na le melemo ea ho hanyetsa mocheso o phahameng, ho hanyetsa serame, ho hanyetsa khatello, ho hanyetsa ho hloekisa, eseng feela ho ka ba libaktheria tsa mocheso o phahameng, hape o ka bolokoa mocheso o tlaase. Khalase e phahameng ea borosilicate e boetse e tsejoa e le khalase e thata, ke mokhoa o tsoetseng pele o entsoeng ka ho sebetsa.

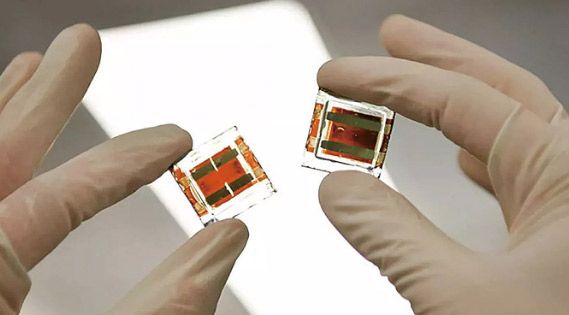

Khalase ea Borosilicate 3.3 ke mofuta oa khalase e khethehileng e sebelisoang lits'ebetsong tse ngata tsa indasteri le tsa mahlale. E na le khanyetso e matla ea mocheso ho feta khalase e tloaelehileng, e e lumellang hore e sebelisoe lits'ebetsong tse ngata tse fapaneng joalo ka lisebelisoa tsa laboratori, lisebelisoa tsa bongaka le li-chips tsa semiconductor. Khalase ea borosilicate 3.3 e boetse e fana ka ts'ebetso e phahameng ea lik'hemik'hale le ho hlaka ha optical ha e bapisoa le mefuta e meng ea likhalase.

Litšobotsi

Ho hanyetsa mocheso o ikhethang

Ponaletso e phahameng haholo

Ho tšoarella ha lik'hemik'hale tse phahameng

E babatsehang matla a mechine

Melemo

Ha ho tluoa tabeng ea tšebeliso ea theknoloji ea borosilicate khalase ea semiconductor chip, ho na le melemo e mengata ea thepa ena ho feta li-chips tsa setso tse thehiloeng ka silicon.

1.Borosilicate e ka sebetsana le mocheso o phahameng ntle le thepa ea eona e fetohang mocheso kapa liphetoho tsa khatello joaloka silicon e ne e tla ha e pepesehetse maemo a feteletseng. Sena se li etsa hore li tšoanelehe bakeng sa lisebelisoa tsa elektroniki tsa mocheso o phahameng hammoho le lihlahisoa tse ling tse hlokang taolo e nepahetseng ea mocheso-joalo ka mefuta e itseng ea lasers kapa mochini oa x-ray moo ho nepahala ho lokelang ho ba ka sehloohong ka lebaka la kotsi e ka bang kotsi ea mahlaseli ao a a ntšang haeba a sa behoe ka nepo ka har'a thepa ea bona ea matlo.

2.Borosilicate matla a hlollang a bolela hore lichipisi tsena li ka etsoa tse tšesaane haholo ho feta tse sebelisang li-wafers tsa silicon - motsoako o moholo bakeng sa sesebelisoa leha e le sefe se hlokang bokhoni ba miniaturization joalo ka li-smartphone kapa matlapa a nang le sebaka se fokolang haholo ka hare ho tsona bakeng sa likarolo tse kang li-processor kapa li-module tsa memori tse hlokang matla a mangata empa li na le litlhoko tse fokolang tsa molumo ka nako e le 'ngoe.

Botenya Processing

Botenya ba khalase bo tloha ho 2.0mm ho isa ho 25mm,

Boholo: 1150*850 1700*1150 1830*2440 1950*2440

Max.3660 * 2440mm, Mefuta e meng e hlophisitsoeng e fumaneha.

Ho sebetsa

Liforomo tse sehiloeng esale pele, ts'ebetso ea moeli, ho futhumatsa, ho cheka, ho roala, jj.

Sephutheloana Le Lipalangoang

Palo e fokolang ea taelo: lithane tse 2, bokhoni: lithane tse 50 / letsatsi, mokhoa oa ho paka: mokotla oa lehong.

Qetello

Qetellong, thepa ea borosilicates e babatsehang ea ho kenya motlakase e etsa hore e be likhetho tse kholo bakeng sa meralo e rarahaneng ea li-circuitry moo ho kenya letsoho pakeng tsa lera le leng le le leng ho bohlokoa e le ho thibela li-circuits tse khutšoanyane tse hlahang nakong ea ts'ebetso - e leng ntho ea bohlokoa haholo ha e sebetsana le maqhubu a phahameng a ka bakang tšenyo e ke keng ea etsolloa haeba ho lumelloa maqhubu a sa thijoeng a phallang libakeng tse thata ka har'a sekepe. Sena sohle se kopanya hammoho ho etsa khalase ea borosilicate 3.3 tharollo e loketseng ka ho khetheha neng kapa neng ha ho hlokahala lisebelisoa tse tšoarellang haholo tse sebetsang ka mokhoa o ts'epahalang tlas'a maemo a feteletseng ha li ntse li fana ka litšobotsi tse ikhethang tsa ho itšehla thajana. hobane lisebelisoa tsena ha li tšoeroe ke oxidation (mafome) joalo ka likarolo tsa tšepe, li loketse ho ts'epahala ha nako e telele libakeng tse thata moo ho pepeseha ho ka lebisang litšepe tse tloaelehileng ho senyeha ha nako.